Zhi Li, FLEET Scientific Associate Investigator, UNSW

The Challenge

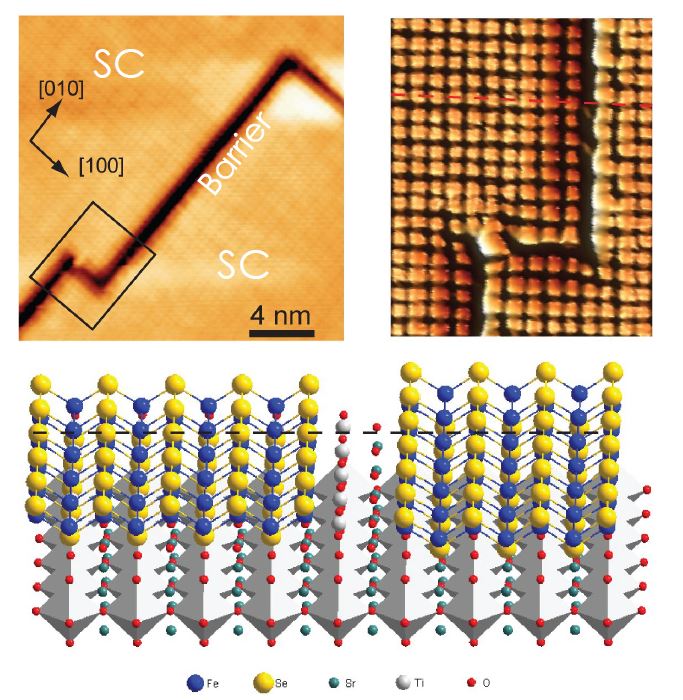

Figure 1: The top-left and bottom-right regions of the atomically thin FeSe superconductor are separated by a 0.6 nm-wide structural gap, which being narrower than the lateral coherence length, functions as the insulating barrier in the desired Josephson junction.

Superconducting electronic devices indeed have a broad range of applications, including single photon detectors, Josephson Junction Devices, High-Frequency and RF Electronics, and Superconducting Quantum Bits. However, a notable challenge in the field of superconducting electronic devices is that conventional metal superconductors can only operate at extremely low temperatures, typically only a few Kelvin. Additionally, fabricating electronic devices using copper-based superconductors poses significant challenges.

The Solution

We have successfully fabricated thin films of the high-temperature superconductor FeSe, which operates at 65 K. FeSe, being a softer material compared to Cu-based superconductors, offers advantages for device fabrication. We have achieved a nanometer-scale gap between two FeSe superconductors, making them suitable for Josephson Junction Devices when electrodes are applied.

Key Benefits

- Working at high-temperature

- Easy fabrication

Development Stage

- Technology concept completed

- Seeking strategic partners

Brief Description & Differentiation

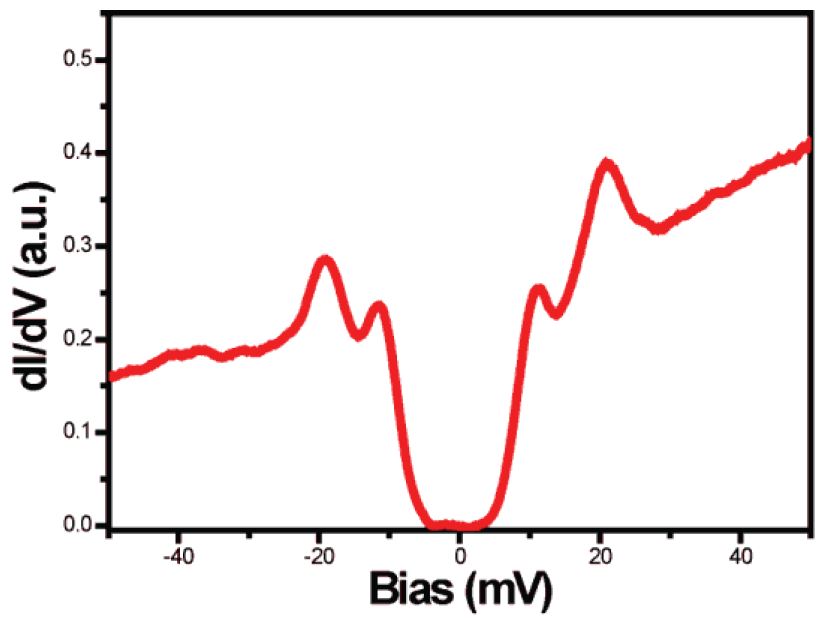

Figure2: The device’s large U-shaped superconducting energy gap (20 meV) is well-suited for single-photon detection.

Our FeSe thin films exhibit the highest superconducting temperature among iron-based superconductors, which translates to more cost-effective cooling. Additionally, they possess a notably large U-shaped superconducting gap of 20 meV (see Fig. 2), making them well-suited for high-frequency photon detection. This is a capability not easily achieved with conventional superconductors (due to their small gap) or Cu-based superconductors (which have a V-shaped gap). In the case of Cu-based superconductors, the fabrication of high-quality Josephson junctions is exceptionally challenging due to their small coherence length and complex chemical composition. We have successfully overcome one of the most challenging steps in creating FeSe Josephson junctions, which is establishing the insulating barrier. Figure 1 illustrates that the width of this barrier is atomically uniform and features a known, precise atomic structure

Intellectual Property

- “High-temperature superconducting film”, US Patent 9461233

- “Method for making high-temperature superconducting film”, US Patent 9425375 (2016)

Key Publications

- Chin. Phys. Lett. 29, 037402 (2012). Cited 1460 times

- Phys. Rev. B (Rapid Commun.) 91,060509 (R) (2015)

More information

- Contact Dr Zhi Li, UNSW Sydney, zhi.li5@unsw.edu.au